Energy savings

What a Hunter Industrial HVLS Fan Can Do for Energy Savings.

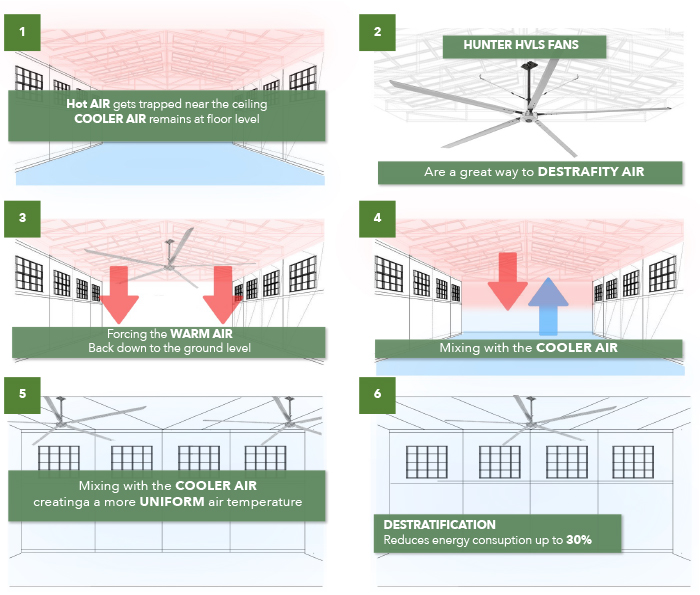

Concept of De-stratification

Hunter industrial fans are designed for de-stratification, aimed at reducing hot and cold spots by mixing air in large industrial and commercial spaces. This results in significant energy cost reduction and increased comfort. Over time, a continuous air mix will promote a more uniform temperature profile from floor to ceiling.

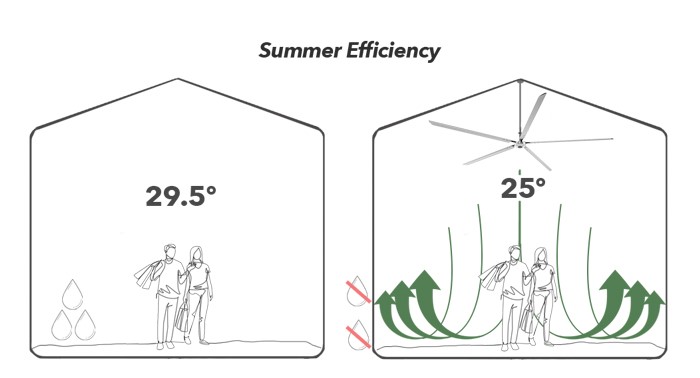

Energy Savings During Summer with the Hunter HVLS Fan

- Immediate reduction of energy costs by over 30%.

- Decrease human thermal comfort sensation by up to 8°C.

- Lower relative humidity by more than 30%.

- Enhance comfort, efficiency, and productivity in the workplace.

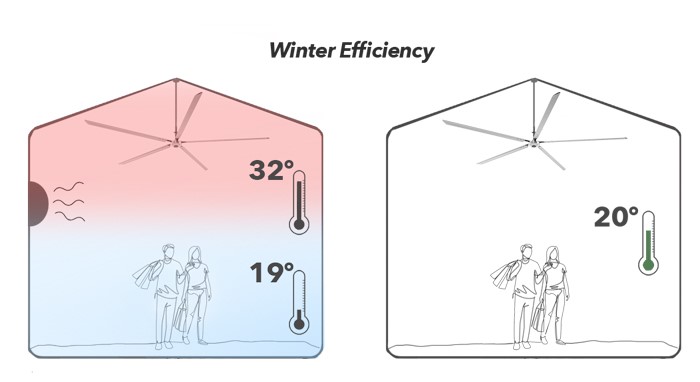

Energy Savings During Winter with the Hunter HVLS Fan

- Reduce heating costs by more than 30%.

- De-stratify temperature throughout the space.

- Eliminate condensation effect.

- Maximize Comfort, Efficiency, and Productivity in the Workplace.

De-stratify Your Space with Hunter Industrial HVLS Fans.

Comfort

The ceiling fans you have in your workspace or living area work by providing that comfortable breeze and airflow designed to cool the skin or even to circulate air around working machinery or help distribute warm air in winter.

How can a Hunter Industrial HVLS Fan make a difference in your facilities?

Creating a safe environment and managing indoor air quality in large facilities, such as industrial warehouses, manufacturing plants, and distribution centers, can be a challenge on multiple fronts..

You can turn to HVAC industrial ventilation units and high-speed floor fans, but these traditional options often don’t provide comprehensive solutions. Our alternative is HVLS (High-Volume, Low-Speed) fans, which can mobilize and de-stratify large volumes of air in a way that truly ‘cleans the air’ in any facility. This enables HVAC systems to:

- Operate more efficiently.

- Optimize employee comfort.

- Enhance productivity.

- Promote a healthier environment.

Employers are responsible for mitigating known environmental safety risks in their facilities, making investment in environmental control solutions like HVLS fans not just a benefit but a critical necessity.

Humidity Control

Humidity control is not only crucial for air quality but also essential when considering condensation.

Condensation can pose a significant safety risk. With proper airflow, condensation can be dried up, reducing the risks of slips, as well as contaminants and bacteria associated with moisture.

Excess humidity can corrode metal products and damage corrugated cardboard boxes. Increased airflow is key to controlling condensation and corrosion. The air movement generated by an HVLS fan can prevent condensation from settling on the floor or products.

In addition to employee health, poor air quality can also pose risks to product quality control, leading to deterioration.

Employers are responsible for mitigating these known safety risks. Investing in products and solutions that help ensure environmental standards, such as HVLS fans, is not just an advantage but a mandate.

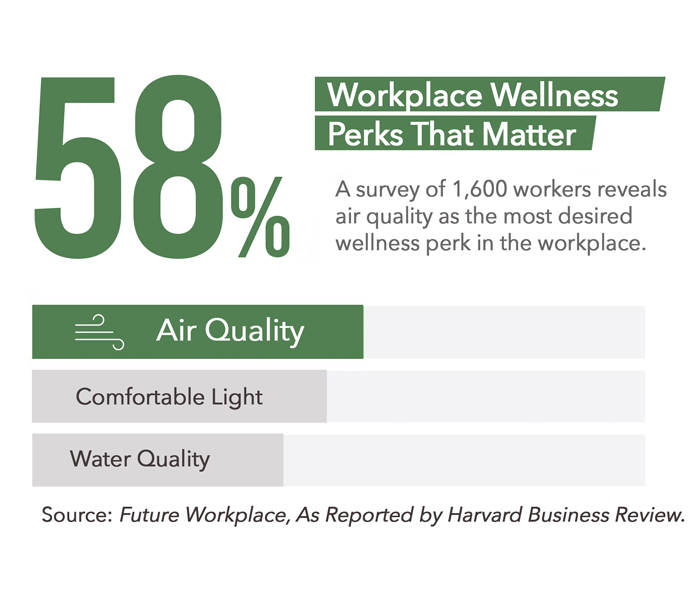

Air Quality

What is Indoor Air Quality?

Indoor air quality is the quality of the air within and around buildings and structures, particularly concerning the health and comfort of the building occupants.

How can poor air quality affect us?

Poor air quality can lead to health effects that are not always experienced immediately after exposure, causing some side effects to appear years later.

How can the HVLS fan improve indoor air quality??

Especially in today’s times, air quality is extremely important for health. HVLS fans move large volumes of air while not dispersing allergens and irritating dust. It helps eliminate stagnant air.

HVLS fans can increase the supply of air within a building to prevent the spread of viruses within it.

Air pollution, whether indoors or outdoors, is a major concern in terms of environmental health, as it can lead to serious health effects such as respiratory diseases, including asthma and lung cancer.

In Europe, significant progress has been made in improving outdoor air quality, and limit values for various pollutants have been established. However, indoor air quality also requires attention because it’s where we spend most of our time.

Assessing the health risks of indoor air pollution is challenging, as indoor air can contain over 900 chemicals, particles, and biological materials with potential health effects. Factors such as ventilation, cleanliness, building characteristics, household products, cultural habits, climate, and the external environment all influence indoor air quality. Hence, significant variations are expected across the EU.

The Scientific Committee on Health, Environmental and Emerging Risks (SCHEER) is one of the three independent non-food scientific committees advising the European Commission on consumer safety, public health, and the environment.

The Scientific Committee on Health, Environmental and Emerging Risks (SCHEER) of the European Commission concludes:

- The principles used in the EU for chemical risk assessment should also apply to indoor air.

- Further research and data are needed, particularly on particles and microbes, volatile organic compounds from consumer products, building humidity, exposure levels, and effects on vulnerable populations.

- Knowledge gaps must be addressed through multidisciplinary research at a European scale.

- The most concerning indoor air pollutants are carbon monoxide, formaldehyde, benzene, nitrogen oxides, naphthalene, environmental tobacco smoke, radon, lead, and organophosphorus pesticides.

The SCHEER also recommends:

- Data on the combined effects of indoor pollutants should be collected.

- All possible exposure pathways should be considered.

- Health-based guideline values for key pollutants and other practical guidance should be developed.

- The impact of indoor exposure should be considered when assessing health effects of outdoor air pollution.

- All relevant sources known to contribute to indoor air pollution should be evaluated.

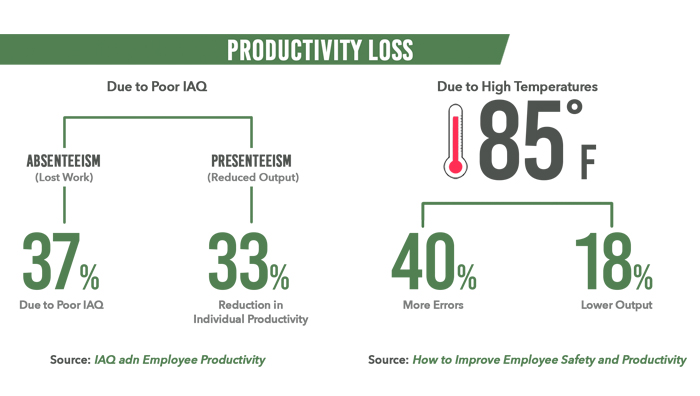

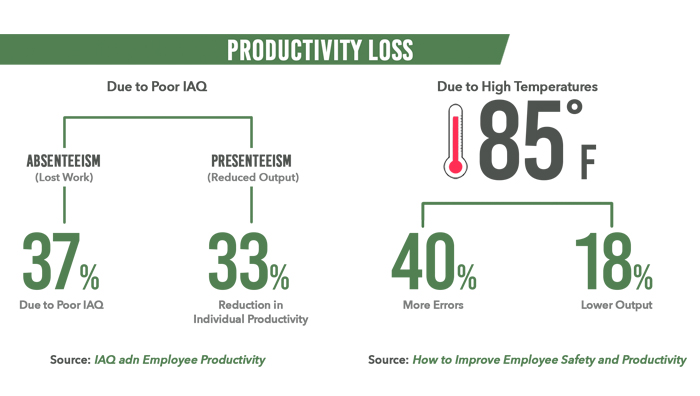

Productivity

Defining and Measuring Productivity.

While air quality and climate control are essential factors to consider, understanding the environment within your building space is also crucial for assessment. Productivity is a critical factor in production.

HVLS maintains the freshness and productivity of your business.

Considering all these factors, HVLS fans emerge as a comprehensive solution to enhance energy savings, cost-efficiency, and safety and health conditions for workers. Regardless of your industry, a company’s success ultimately hinges on the safety and health of its personnel. It’s proven that safety is related to the air employees breathe. The importance of building air circulation and management cannot be underestimated. Investments in the right HVLS solution for your facilities can lead to a radical transformation in a company’s well-being standards while driving its results.

Improving your company’s outcomes matters to us. Hunter Industrial’s HVLS fans focus on efficiency and ease and are designed to provide optimal comfort in work environments.

Defining and Measuring Productivity.

While air quality and climate control are essential factors to consider, understanding the environment within your building space is also crucial for assessment. Productivity is a critical factor in production.

HVLS maintains the freshness and productivity of your business.

Considering all these factors, HVLS fans emerge as a comprehensive solution to enhance energy savings, cost-efficiency, and safety and health conditions for workers. Regardless of your industry, a company’s success ultimately hinges on the safety and health of its personnel. It’s proven that safety is related to the air employees breathe. The importance of building air circulation and management cannot be underestimated. Investments in the right HVLS solution for your facilities can lead to a radical transformation in a company’s well-being standards while driving its results.

Improving your company’s outcomes matters to us. Hunter Industrial’s HVLS fans focus on efficiency and ease and are designed to provide optimal comfort in work environments.

Return on investment

Hunter Industrial HVLS Fans – Return on Investment (ROI) as a Key Productivity Factor.

When purchasing new equipment or launching a new pricing strategy, ROI is measured based on money saved or earned. However, ROI data is also measured differently: An installation needs to demonstrate business value across the enterprise, as well as financial viability. A facilities manager needs to look beyond cost savings to gauge the value of workforce efforts.

Improving employee satisfaction and investing in facility enhancements creates a workplace where employees enjoy being, which can enhance productivity, ultimately impacting the bottom line. It gives your company a competitive advantage and, ultimately, contributes to the profit margin.

1.- Facility Upgrades for Improved Health with HVLS

Fans can help regulate temperature, prevent stagnant air, control humidity, and promote a cleaner working environment.

2.- Enhanced Productivity Enhances ROI Metrics

By creating a more comfortable and healthier work environment, companies can experience reduced absenteeism and employee complaints, along with an overall increase in productivity.

3.-Financial Business Impact of ROI

An industrial ceiling fan minimizes energy consumption per square foot with a cost savings of approximately $1 per day for operation. An industrial ceiling fan can replace up to 10 or 20 floor fans or twelve 48-inch barrel fans, effectively creating a perceived temperature difference of 10 to 12 degrees in the warmer summer months.

*Dependent on industry channel and investment goals, an average of 1.5 years ROI can be expected.